Copper wire

- Tel:0086 0550 7310999

- Fax:0086 0550 7623508

- Email:xinguoalloy@xinguo.net

Description

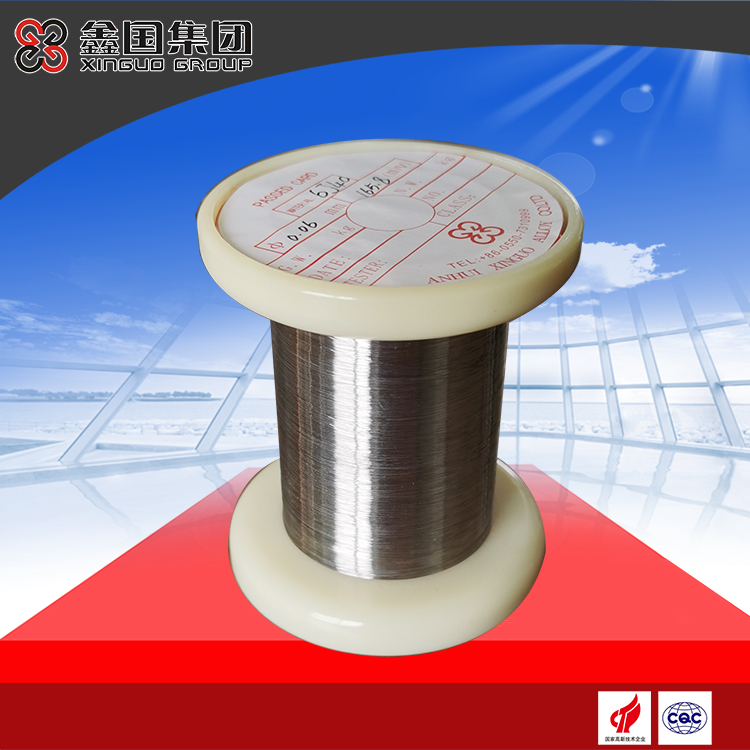

Precision resistance alloy wire

Manganese copper:

With copper, manganese and nickel as the main components, it has the characteristics of high resistivity, small resistance temperature coefficient, thermoelectric potential to copper, and excellent long-term resistance stability. It is a relatively ideal precision resistance material. Mainly used in precision instrument resistance components and shunt resistance.

Copper:

With copper nickel as the main component, it has a low resistance temperature coefficient, a wide temperature range (below 500℃), good machining performance, corrosion resistance. It can make variable resistance and strain resistance components in AC instruments.

Kama (nickel chromium aluminum iron):

Nickel, chromium, aluminum, iron as the main components. The resistivity is about three times higher than that of manganese copper, and has lower resistance temperature coefficient and lower thermoelectric potential to copper, good long-term resistance stability and oxidation resistance. The use temperature is wider than manganese copper. Suitable for making precision micro resistance element and strain gauge.

New copper:

With copper and nickel as the main components, its performance is the same as copper, suitable for manufacturing a variety of resistance rheostat and resistance elements.

Main performance:

Alloy name

| Alloy grade

| resistivity (μω.m) | Resistance temperature coefficient | Thermoelectric potential for Cu Μ v / ℃ | The wire is ** high Service temperature ℃ |

copper | 6J40 | 0.48 + / - 0.03 | 40 mm or less | - 45 | 500 or less |

New copper | 6J11 | 0.3 | 400 or less | ||

Manganese copper | 6J13 | 0.44 + / - 0.04 | 0 ~ 40 | 0 ~ 40 | 0 to 100 |

Karma | 6J22 | 1.33 + / - 0.07 | 20 mm or less | 2.5 or less | 300 or less |

Our company can produce all the above brands of wire, wire diameter up to 0.08mm.